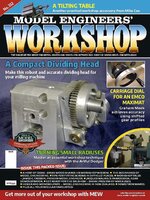

Model Engineers' Workshop is the ideal workshop companion for all hobby engineers. Model Engineers' Workshop shines a spotlight on the tools and techniques used by model makers, light engineers, restorers and customisers and those who like making and modding their own tools. You'll find readers' tips, reviews of workshop equipment as well as articles on restoring old tools and making your own as well as the latest new technologies, techniques and materials. Model Engineers' Workshop magazine publishes 12 great issues a year.

Model Engineers' Workshop

On the Editor's Bench

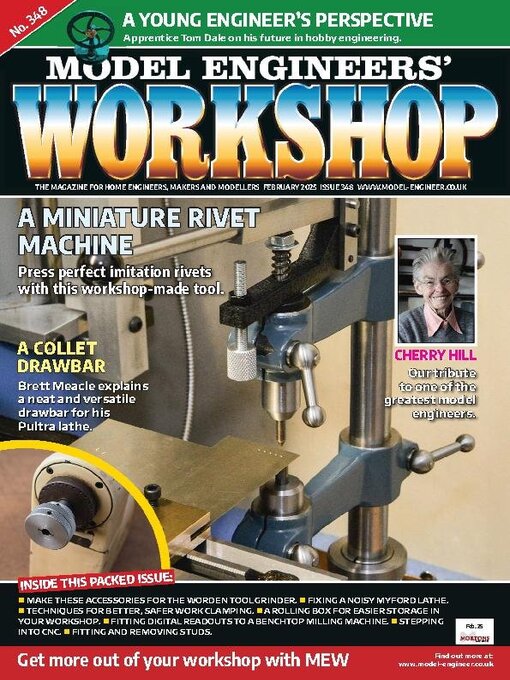

A Tribute to Cherry Hill • In 2008, former MEW Editor Geoff Sheppard and photographer Justin Lambert visited the late Cherry Hill to talk to her about her workshop and models. This article appeared only in a 'special' magazine and we reproduce it here in tribute to one of the finest model engineers of our age.

A Rolling Box • Jacques Maurel has an idea that involves recycling one of the artefacts of his youth!

3D printing: a Young Engineer's perspective on innovation and potential • Tom Dale is an apprentice engineer the editor met at the Midlands Exhibition. Here he shares his thoughts on 3D printing, offering an insight in to what could inspire the next generation of model engineers.

Making a Pultra Lathe Collet Drawbar • Brett Meacle describes how he made a versatile collet drawbar to a design that is easily adapted for other lathes that use threaded draw-in collets.

From the Archives

Accessories for the Worden Tool and Cutter Grinder • Rod Jenkins explains some fixtures for the Worden, many of which are adaptable to other workshop grinders.

Cherry Hill, 1931 - 2024

NEWS from the World of Engineering

A Model Riveting Attachment • Adrian Garner makes an elegant accessory for George H. Thomas’ Pillar Tool.

A Noisy Problem • Laurie Leonard had noticed a noise coming from the clutch operating area on his Myford ML7 lathe for a while, but it suddenly got worse and the operating lever started to dance about.

Scribe a line • YOUR CHANCE TO TALK TO US!

Readers' Tips

Measuring the "Frankenstein mill" • Brian Wood has previously described how he grafted parts of two milling machines together. Here he details how he fitted a Newall digital read out (DRO) system.

STUD FITTING AND REMOVAL

First Steps in CNC part 2 • Mark Noel concludes his experiences of CNC by discussing improvements to his machine.

Resources

Sep 01 2025

Sep 01 2025

Aug 01 2025

Aug 01 2025

Jul 01 2025

Jul 01 2025

Jun 01 2025

Jun 01 2025

May 01 2025

May 01 2025

Apr 01 2025

Apr 01 2025

Mar 01 2025

Mar 01 2025

Feb 01 2025

Feb 01 2025

Jan 01 2025

Jan 01 2025

Dec 01 2024

Dec 01 2024

Nov 01 2024

Nov 01 2024

Oct 01 2024

Oct 01 2024

Sep 01 2024

Sep 01 2024

Aug 01 2024

Aug 01 2024

Jul 01 2024

Jul 01 2024

Jun 01 2024

Jun 01 2024

May 01 2024

May 01 2024

Apr 01 2024

Apr 01 2024

Mar 01 2024

Mar 01 2024

Feb 01 2024

Feb 01 2024

Jan 01 2024

Jan 01 2024

Dec 01 2023

Dec 01 2023

Nov 01 2023

Nov 01 2023

Oct 01 2023

Oct 01 2023